With PTFE Mesh Conveyor Belt You Can Diy Conveyor Dryer Screen Printing

Screen printing is a popular printing technique that involves applying ink onto a flat surface using a stencil and a squeegee. One of the key components of the screen printing process is drying the ink, which can be done using a conveyor dryer. While commercial conveyor dryers can be expensive, it is possible to make your own DIY conveyor dryer using a few basic materials and a PTFE mesh conveyor belt. In this article, we’ll guide you through the process of making your own DIY conveyor dryer for screen printing.

Materials Needed

To make a DIY conveyor dryer for screen printing, you will need the following materials:

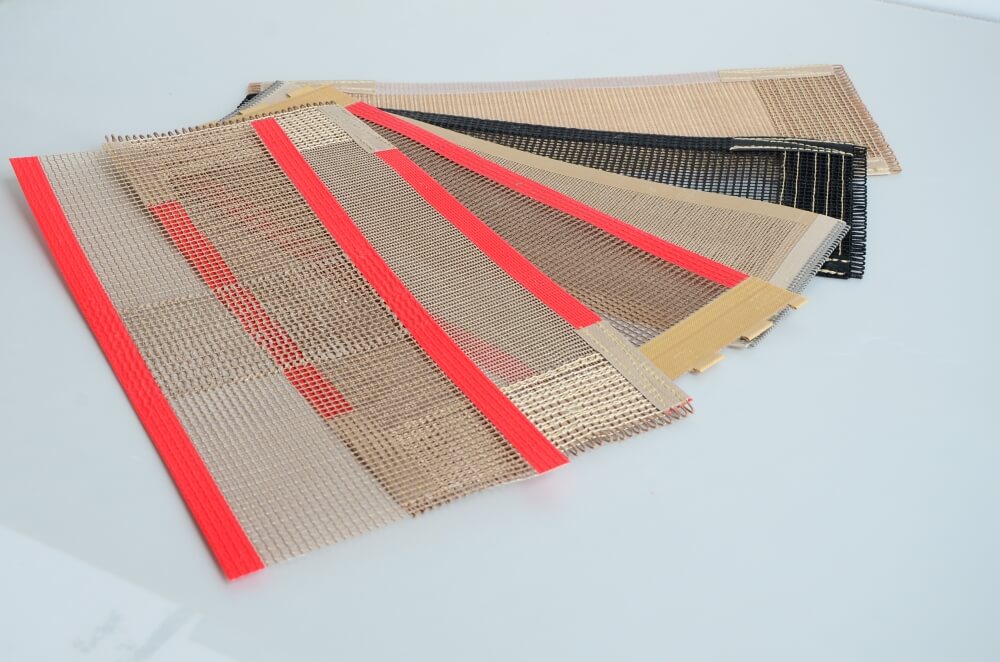

- A PTFE mesh conveyor belt

- Aluminum angle bars

- Steel bars or rods

- Metal cutting saw

- Metal drill

- Metal screws

- Heat gun or hot air gun

- Thermocouple

Step-by-Step Guide

- Cut the Aluminum Angle Bars

The first step in making your own DIY conveyor dryer is to cut the aluminum angle bars to the desired length. The length of the bars will depend on the size of the conveyor belt and the width of the dryer. Use a metal cutting saw to cut the angle bars to the correct length. - Drill Holes in the Aluminum Bars

Next, use a metal drill to drill holes in the aluminum bars. The holes should be evenly spaced and should be large enough to accommodate the steel bars or rods that will be used to support the conveyor belt. - Attach the Steel Bars or Rods to the Aluminum Bars

Using metal screws, attach the steel bars or rods to the aluminum bars. The steel bars or rods should be threaded through the holes in the aluminum bars and should be securely fastened in place. - Install the PTFE Mesh Conveyor Belt

Lay the PTFE mesh conveyor belt on top of the steel bars or rods, making sure that it is evenly spaced and centered on the dryer. The PTFE mesh conveyor belt should be cut to the correct length before installation. - Install the Thermocouple

Install a thermocouple on the conveyor dryer to monitor the temperature. The thermocouple should be placed close to the conveyor belt to accurately measure the temperature of the ink as it dries. - Use a Heat Gun or Hot Air Gun to Dry the Ink

Finally, use a heat gun or hot air gun to dry the ink on the screen. The heat gun or hot air gun should be set to the correct temperature for the ink being used. Use the thermocouple to monitor the temperature and adjust the heat as necessary to ensure that the ink dries evenly and thoroughly.

In conclusion, making your own DIY conveyor dryer for screen printing is a cost-effective way to dry ink on a screen. By using a PTFE mesh conveyor belt, you can ensure that the ink dries evenly and thoroughly without sticking to the conveyor belt. With a few basic materials and some basic metalworking skills, you can create a conveyor dryer that will be reliable and effective for your screen printing needs.